-

Maintenance Management Software

Prevent Downtime

with Automated Maintenance

with Automated Maintenance

Schedule and manage maintenance tasks effortlessly. Reduce downtime, track asset performance, and ensure equipment longevity with preventive maintenance tools.

Chosen by the Teams That Keep Operations Running

Asset Tracking

Track Your Assets with Ease

Keep a detailed inventory of all your assets. Monitor performance, service history, and condition in one centralized platform, ensuring optimal utilization.

Preventive Care

Shift from Reactive to Proactive Maintenance

Transform your maintenance strategy. Schedule preventive maintenance tasks to reduce downtime and extend the lifespan of your assets.

Work Order Management

Simplify Work Order Creation

Easily create, assign, and manage work orders. Track progress and ensure timely completion, all while improving team accountability.

Mobile Access

Empower Your Maintenance Team

Provide field technicians with mobile access to work orders, maintenance logs, and asset details. Enhance productivity with real-time information on-the-go.

Data-Driven Decisions

Generate Insights with Detailed Reports

Access customizable reports to analyze maintenance performance. Identify trends, track costs, and make informed decisions to optimize your maintenance strategy.

Intuitive Design

Navigate with Ease

Enjoy a clean and intuitive interface that makes maintenance management simple for everyone. Get started quickly and reduce training time for your team.

Armed with all the necessary tools

for Maintenance

Maintenance Scheduling

Inspections & Audits

Asset Tracking

Asset Management

Paperless Environment

Predictive Alerts

Work Orders

Preventive Scheduling

Inventory Management

Condition Monitoring

Vendor Management

Mobile Access

Perfect fit for every team

Get started fast with out-of-the-box solutions.

Easily customize flowdit as team needs grow!

CONSTRUCTION

flowdit enhances efficiency, reduces delays, boosts productivity, ensures safety.

Project Manager

Granted Works Contractors

LOGISTICS

flowdit unifies operations, boosts efficiency, and enhances team collaboration.

Operations Manager

Loadtrack Logistics

ENERGY

flowdit streamlines processes, boosts efficiency, and empowers innovation.

Sun Horizon Energy Solutions

AVIATION

flowdit transforms operations, ensuring clarity, adaptability, and team alignment.

Chief Operations Officer

SkyTrack Aviation Services

MANUFACTURING

flowdit enhances efficiency, ensures compliance, simplifies processes, and saves time.

Quality Assurance Manager

IronEdge Fabrications

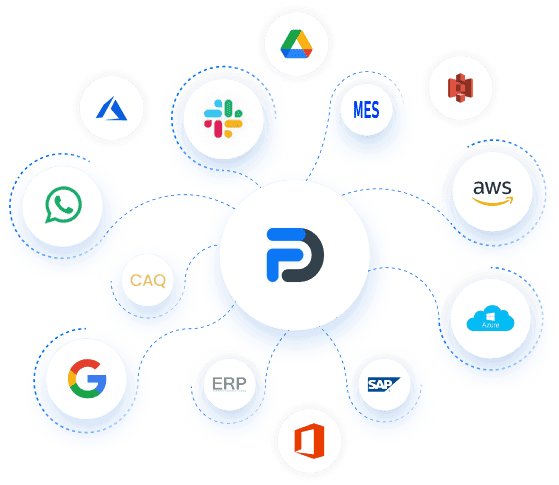

Integrated Maintenance Solutions for Reliable Operations

flowdit simplifies your operations by integrating with ERPs and project management tools. Optimize production processes and deliver better outcomes.

Enhancing Operational Efficiency with flowdit’s Maintenance Management Software

Optimize Your Workflow Today!

Simplify processes, enhance compliance, and boost efficiency with flowdit’s all-in-one platform. Revolutionize your workflows today.

Got questions?

Frequently Asked Questions

What is maintenance management software?

Maintenance management software is a specialized tool that helps organizations streamline and optimize the upkeep of their assets, including machinery, equipment, and facilities. It provides a centralized platform to track asset performance, schedule maintenance activities, and ensure timely inspections and repairs.

As part of a suite of maintenance management solutions, it focuses on maintenance management to address critical operational needs and improve reliability. By focusing on preventive maintenance strategies, the software reduces unplanned downtime and extends the lifespan of critical assets.

Widely used in manufacturing, transportation, and healthcare industries, this software enhances operational efficiency by minimizing disruptions and maximizing resource utilization.

Maintenance management software often integrates with asset management software to provide comprehensive oversight of equipment and resources. CMMS features, such as work order tracking, inventory management, and automated reminders, further enable teams to stay proactive and organized in maintaining their assets.

What features should I look for in a CMMS or maintenance software?

When selecting maintenance management software, there are a few key factors to consider. Firstly, look for essential features that can streamline your maintenance processes. These may include work order management, preventive maintenance scheduling, asset tracking, inventory management, and robust reporting capabilities. Ensure the software supports maintenance tracking to monitor all activities effectively and includes robust capabilities to provide a clear overview of all activities while facilitating data-driven decision-making.

It should also operate as a versatile asset management platform, enabling seamless integration of asset data into your workflows to improve utilization and extend asset lifecycles. Furthermore, the system should track asset maintenance histories to support better long-term planning and decision-making.

How important is the ease of use when selecting maintenance software?

Ease of use is a critical factor to consider when assessing maintenance management software. Opt for software that offers an intuitive interface, enabling your team to navigate and utilize its features efficiently while enhancing maintenance operations.

Look for solutions that simplify maintenance activities while supporting effective asset operations management platform capabilities. This means selecting a system that allows for easy data entry, seamless information access, and streamlined workflows, such as creating maintenance work orders or managing recurring maintenance without requiring extensive training.

Can the CMMS integrate with other software systems we use?

Yes, integration capabilities are essential.

Choose a CMMS that can seamlessly integrate with your existing ERP, accounting, or inventory systems. These integrations allow you to track asset maintenance in real-time while providing a unified view of your operations. Additionally, connecting with tools like asset and inventory management software boosts process efficiency and ensures that all systems work together smoothly. A digital maintenance management system further enhances workflows by addressing maintenance issues proactively and effectively.

Opt for software that adapts to your operational needs and improves overall system compatibility and functionality.

Is it necessary for the CMMS to be scalable?

Absolutely, scalability is a crucial factor when selecting maintenance work order software for your organization.

The software should be capable of accommodating growth by supporting more users, assets, and expanding schedules. A scalable software solution ensures the system remains robust and continues to facilitate preventative maintenance even as your organization's complexity increases.

Opt for a system that improves maintenance management processes, enabling your team to stay organized and efficient during periods of growth. Ensure the software allows for easy customization and integration to meet the unique demands of your evolving operations.

What kind of vendor support and training should I expect with a CMMS?

When searching for vendors, prioritize those that offer comprehensive support services.

These should include technical assistance, regular software updates, and training resources. A vendor that provides access to a free version or a Free Maintenance Management Software option ensures you can evaluate its features before full implementation. Strong support and accessible maintenance planning resources maximize the value of your investment while helping you automate tasks like preventive maintenance and work order creation. A well-structured maintenance strategy enhances these benefits by aligning maintenance planning with long-term operational goals, reducing downtime, and optimizing resource allocation.

Choose CMMS solutions that serve as versatile management tools, enabling effective asset management. Additionally, ensure the management software provides seamless integration capabilities to streamline your operations and boost efficiency.

What are the benefits of using CMMS software?

Centralized Information:

A single source of truth ensures clear communication, reduces errors, and aligns maintenance teams with accurate, up-to-date information, forming the backbone of any effective maintenance platform.

Proactive Maintenance:

By automating preventive schedules and enabling predictive maintenance through condition monitoring, it minimizes downtime and cuts repair costs. These features are essential for a robust preventive maintenance program that ensures long-term asset performance.

Streamlined Work Orders:

Automated work order management eliminates manual errors and accelerates task completion, boosting workflow efficiency. This simple maintenance approach saves time while ensuring tasks are completed accurately.

Inventory Automation:

Real-time tracking and automated reordering ensure spare parts are available, avoiding costly delays. With CMMS maintenance tools, managing inventory becomes a seamless part of the overall maintenance strategy.

Data-Driven Decisions:

Dashboards and analytics provide actionable insights into performance, costs, and productivity for better planning. These insights allow enterprises to fine-tune their enterprise asset management processes, optimizing both assets and resources.

Simplified Compliance:

Digitized records facilitate audits and ensure adherence to safety standards with centralized, easily accessible documentation. This is a critical feature of any reliable maintenance platform, helping organizations avoid compliance risks.

Improved Safety:

By supporting regulatory compliance and safety protocols, it creates a safer, more reliable work environment, protecting both employees and assets.

How can CMMS software help to ensure compliance and safety standards?

CMMS software ensures compliance and safety by tracking and documenting maintenance requests, ensuring tasks are completed on time. It identifies potential safety hazards and monitors corrective actions, promoting a safer work environment. By leveraging key features of the CMMS , organizations can streamline workflows and gain better control over their operations. Additionally, maintenance professionals benefit from tools that simplify task allocation and improve communication within teams. Features like dashboard views provide instant oversight of critical compliance metrics, making it easier to manage a robust maintenance program.

How can CMMS software help to extend asset lifespan?

By providing a systematic approach to asset maintenance, CMMS software helps extend the lifespan of equipment.

It tracks maintenance schedules, automates preventive maintenance, and monitors maintenance work, ensuring potential issues are addressed before escalating into costly problems. With a robust maintenance management solution you can efficiently manage work orders, streamline workflows, and improve operational efficiency. The type of maintenance management software is designed to help organizations schedule and track preventive maintenance, reducing the risk of unexpected downtime. Additionally, it allows you to track maintenance history, and optimize performance and reliability, enabling better decision-making and resource allocation.

CMMS software also supports both preventive and corrective maintenance, ensuring all aspects of asset care are covered. For businesses utilizing asset management systems, it offers seamless integration, ensuring a unified view of operations. The ability to get your maintenance scheduled and view it in real-time further enhances efficiency and oversight, ensuring proactive management of all assets.

Who Uses Maintenance Management Software?

The software is commonly used by professionals in roles such as:

Maintenance Supervisors: Review and validate SOPs or audit findings to align with best maintenance practices. Oversee preventive maintenance (PM) schedules and asset mobility.

Machine Operators: Inspect machinery for wear and tear, report issues through work requests, and rely on precision tools like image recognition for complex part installations.

Reliability Engineers: Analyze maintenance data to create charts and diagrams, balancing cost constraints with process availability.

Technicians: Identify asset failure codes, complete work orders, and retrieve necessary parts to restore assets as conditions decline.

Executive Leaders: Assess business performance by comparing production costs to profits and allocate budgets for strategic initiatives.

Inventory Managers: Manage inventory records, adjust spare part quantities, and prevent shortages or overstocking in warehouses.

Facility Managers: Monitor building systems such as HVAC and plumbing, schedule inspections, and ensure operational efficiency.

Health and Safety Officers: Identify workplace hazards, log safety incidents, and ensure compliance with safety standards.

Environmental Compliance Officers: Track environmental impact, document adherence to regulations, and support sustainability initiatives.

Quality Assurance Inspectors: Evaluate asset conditions to meet quality standards and track corrective actions using the software.