-

Manufacturing Operations Management Software (MOM)

Simplify, Optimize, and Scale Your Operations

Chosen by the Teams That Keep Operations Running

Reduce Downtime

Maintain Optimal Production Flow

Gain real-time visibility into your production line to identify bottlenecks and reduce downtime. Enhance productivity with actionable insights tailored to your operations.

Empower Teams

Enable Seamless Cross-Team Collaboration

Use solutions that streamline scheduling and team communication, ensuring all staff remain aligned to meet deadlines and quality standards.

Stay Audit-Ready

Empower Performance Through Regulatory Data Alignment

Track compliance requirements automatically and produce thorough reports in a matter of seconds. Stay prepared for audits and maintain high standards across every project.

Real-Time Insights

Optimize Operations Using Data

Use advanced analytics to predict demand, optimize resource allocation, and reduce waste. Make data-driven decisions supported by precise, actionable insights.

Future-Ready Technology

Scale Smoothly, Achieve More

flowdit adjusts to your needs, whether you're expanding or improving current operations. Build a resilient, scalable system that grows with your manufacturing business.

Maximize Efficiency with a Complete Manufacturing Operations Suite

Cross-platform compatibility

Secure cloud storage

IoT sensor integration

Real-time collaboration

Offline functionality

Automated workflows

No-code form builder

Data analytics and reporting

GPS tracking

Multi-language support

Mobile-first design

Role-based access control

Perfect fit for every team

Get started fast with out-of-the-box solutions.

Easily customize flowdit as team needs grow!

CONSTRUCTION

flowdit enhances efficiency, reduces delays, boosts productivity, ensures safety.

Project Manager

Granted Works Contractors

LOGISTICS

flowdit unifies operations, boosts efficiency, and enhances team collaboration.

Operations Manager

Loadtrack Logistics

ENERGY

flowdit streamlines processes, boosts efficiency, and empowers innovation.

Sun Horizon Energy Solutions

AVIATION

flowdit transforms operations, ensuring clarity, adaptability, and team alignment.

Chief Operations Officer

SkyTrack Aviation Services

MANUFACTURING

flowdit enhances efficiency, ensures compliance, simplifies processes, and saves time.

Quality Assurance Manager

IronEdge Fabrications

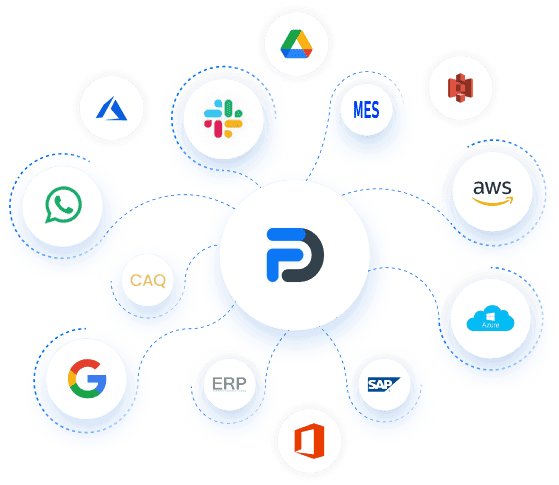

Unlock Peak Manufacturing Performance with Connected Tools

flowdit connects effortlessly with your ERP, CRM, project management, and document systems, streamlining workflows and enabling real-time collaboration throughout your business.

Improve Performance and Quality with flowdit’s Manufacturing Operations Management Software

Transform the way your team works - today.

Simplify processes, stay aligned with every standard, and drive efficiency with flowdit’s all-in-one platform. Power your operations today.

Got questions?

Frequently Asked Questions

What is manufacturing operations management (MOM)?

Manufacturing Operations Management (MOM) is a comprehensive approach to overseeing and optimizing all aspects of production processes within a manufacturing environment.

It combines software tools and strategies to handle production planning, quality control, process execution, and real-time monitoring. Digitalized processes make manufacturing more efficient and adaptable. Time-to-market improves. Manufacturers can respond faster to market demands and disruptions.

MOM goes beyond traditional manufacturing execution systems (MES). It adds maintenance, internal logistics, and supply chain coordination to one platform. It uses MES to ensure quality and efficiency, supporting continuous improvement, minimizing waste, and meeting industry standards. The holistic system offers a unique level of delivery and quality control, providing full visibility into operations and enabling informed decision-making.

By addressing end-to-end manufacturing processes, MOM empowers manufacturers to streamline workflows, reduce downtime, and achieve operational excellence, positioning them to meet evolving customer expectations and maintain a competitive edge in dynamic markets.

What is MOM software?

Manufacturing Operations Management (MOM) software is an integrated platform that manages the entire manufacturing process.

It links production planning, scheduling, quality control, inventory management, and maintenance into one system for shop floor operations. The platform tracks production metrics throughout the manufacturing lifecycle. Manufacturers measure factory performance using metrics like overall labor effectiveness (OLE), overall equipment effectiveness (OEE), and total effective equipment performance (TEEP).

Real-time visibility of operations and control over manufacturing activities lets companies monitor performance, spot inefficiencies, and maintain consistent product quality. MOM applications include predictive analytics to support data-driven decision-making. They also handle production monitoring and provide advanced planning and scheduling to optimize resources.

The software connects departments and aligns operations with business goals. This cuts lead times and reduces waste. Manufacturers gain higher productivity with MOM as part of their production setup.

How can manufacturing operations management software improve manufacturing?

Manufacturing operations management software enhances manufacturing by streamlining processes, reducing waste, and boosting efficiency and profitability.

By integrating lean production principles, manufacturers can eliminate non-value-adding activities and optimize resource utilization. Real-time data insights from digital manufacturing offer comprehensive visibility into shop-floor operations to support informed decision-making. Effective shop floor documentation for production operations is an integral part of these processes, ensuring that critical information is available to all stakeholders. A MOM solution offers a unique level of control and monitoring, enabling operators, supervisors, and plant managers to leverage a suite of industrial applications that enhance visibility into operations and improve overall manufacturing performance.

By automating critical processes and integrating them across operational areas, MOM software enables manufacturers to respond to market demands at all levels of production, ensuring flexibility and adaptability. It helps achieve key goals such as lowering costs, ensuring regulatory compliance, managing inventory effectively, and maintaining high-quality standards. This approach drives efficiency and supports sustainable improvements in manufacturing performance.

How does MOM software support lean manufacturing methods?

MOM software enables manufacturers to implement and sustain lean manufacturing methods by reducing waste, improving process efficiency, and enhancing real-time decision-making. By integrating digital workflows, automated quality control, and predictive maintenance, MOM solutions help maintain continuous improvement cycles.

What types of operations software are available?

- Operations management software

- Manufacturing operations management software

- Operational risk management software

What are the benefits of using operations software?

- Increased efficiency and productivity

- Reduced operational costs

- Improved decision-making

- Enhanced collaboration

- Secure data services

- Reduced risk

What are the features of operations software?

- Process mapping

- Resource management

- Workflow automation

- Performance analytics

- Reporting and dashboards

What are the features of manufacturing operations software?

- Production planning and scheduling

- Inventory management

- Quality control

- Maintenance management

- Equipment monitoring

What industries can benefit from using a MOM system?

MOM software is used across different manufacturing industries to improve efficiency, productivity, and control. Common applications include:

- Automotive Manufacturing: Manages complex production workflows and quality control.

- Aerospace and Defense: Helps meet strict regulations and maintain precision in manufacturing processes.

- Electronics and High-Tech: Tracks and manages multi-stage, high-volume production.

- Industrial Machinery: Improves efficiency and quality in complex assembly through business process management.

- Pharmaceutical and Life Sciences: Supports regulatory compliance and controlled batch production.

- Food and Beverage Processing: Increases efficiency and helps maintain safety and quality standards.

- Consumer Products: Maintains consistent product quality in manufacturing.

- Energy and Utilities: Manages assets and workflows.

- Chemical Processing: Controls production precision and regulatory compliance.

- Medical Equipment: Supports compliance with regulations and process control.

- Metal Fabrication and Machinery: Manages production scale and quality standards.

What is the difference between MES and MOM in manufacturing operations?

MES (Manufacturing Execution System) manages shop floor executio: work orders, production tracking, and real-time data collection.

MOM (Manufacturing Operations Management) is the broader framework. It includes MES plus quality management, maintenance, inventory, and performance analysis.

Simply put: MES handles execution. MOM manages the entire operation.

Most manufacturers need MOM because production execution alone doesn’t give you control over quality, maintenance schedules, or resource allocation. MOM integrates these functions so you can manage operations across the entire manufacturing lifecycle, not just monitor current production status.

How do plant and operations managers benefit from flowdit?

Plant and operations managers use flowdit to enhance operational efficiency and maintain compliance through real-time, automated inspections. The software digitizes workflows, checklists, and audits, streamlining processes, and maintaining consistent quality across production lines. This enables faster decision-making, quicker issue resolution, and improved overall performance.

For more information on how flowdit supports plant managers, visit flowdit.com/plant-managers-real-time-automated-inspection/.