-

Connected Worker Software for Manufacturing

Future of the Connected Worker Software in Industry

Bring your team together across production, field service, maintenance, and commissioning. Go digital, boost efficiency, and improve safety with 360° visibility.

Chosen by the Teams That Keep Operations Running

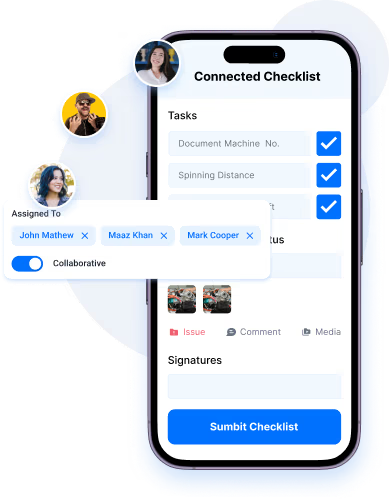

Innovations In Instant Digital Documentation

flowdit excels in document capture, communication, and collaboration, enabling teams to effortlessly work through roadblocks and day to day operations.

- Digitalize everything with on-the-spot capture

- Rapidly collaborate with issue-related chats

- Resolve challenges faster than ever before

Streamlined Onboarding And Employee Training

Make onboarding more effortless and intuitive with your own connected worker solutions. Systematize training with easily digestible digital dmaterials. flowdit – The All-In Connected Worker Software.

- Automate your onboarding process and save both time and resources for higher aims

- Pass the baton with unambiguous task guidelines and clear directions

- Every worker has access to the tools and resources they need most through the app

Ready to get started?

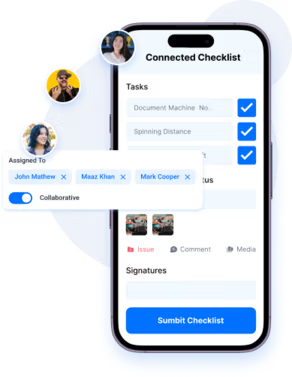

Enabling Connected Remote Workers

In an increasingly remote world, staying connected is paramount to productivity. We help you seamlessly digitize workflows, collaboration, and communication.

- 360° workflow and data visibility in real time.

- Instant communication for always-on-time collaboration

- Universally high standards across all territories

Connected Worker Software: Advanced Analytics

Lead your team with decisions based on real-time data. Unlock insights and trends with dashboards and analytics designed around KPIs.

- Comprehensive insights into workforce performance with data visualization

- Discover opportunities and bottlenecks quickly

- Make optimal resource distribution and strategic decisions with multiple sources of data

Seamless Integration With Third-Party Systems

flowdit is super-connective with today’s leading systems and databases, thanks to our serverless microservice architecture.

- “Plug-and-play” interfaces enable easy (almost effortless!) third-party integrations

- Our unparalleled scalability allows you to grow virtually without any limits

- Data can easily be migrated across multiple platforms for analysis and management

The ultimate solution for any team

Get started now with out-of-the-box solutions.

Easily customize flowdit as your team's needs evolve!

PMP Service GmbH

CEO

"With flowdit, PMP GmbH has successfully implemented its own assessment process in the marine industry. flowdit contributes significantly to the optimization of our processes and services."

EG Group

Public Affairs & Corporate Services Manager

"flowdit represents significant progress in the EG Group's compliance management and is an indispensable pillar of our strategy to digitalize and increase efficiency."

Schuler Pressen GmbH

Technical Sales Engineer Digital Solutions

"Dramatically maintain clicks-and-mortar solutions without functional solutions. Completely synergize resource taxing relationships via premier niche markets. Professionally cultivate."

Transform the way your team works - today.

Simplify processes, stay aligned with every standard, and drive efficiency with flowdit’s all-in-one platform. Power your operations today.

FAQ: Connected Worker Platform (CWP)

What is flowdit’s Connected Worker Platform?

flowdit is a digital system that connects frontline workers, processes, and data in real time across the manufacturing plant. It goes beyond simple communication or documentation by linking guided checklists, audits, and maintenance activities with live feedback, analytics, and AI-driven insights. Every action taken by frontline workers becomes structured data, enabling consistent improvement, traceability, and operational excellence

Which industries gain the most from flowdit’s Connected Worker Platform?

flowdit brings connected worker technology to industries with frontline operations: including manufacturing, construction, energy, healthcare, and logistics. It standardizes workflows, captures real-time data, and ensures full traceability across processes. Wherever safety, compliance, and efficiency matter, flowdit delivers measurable improvement.

What features are included in flowdit’s Connected Worker Platform?

flowdit includes issue reporting, field service coordination, digital work instructions, checklist and form management, and task management. It also provides real-time data analytics, seamless communication tools, and integration with systems like ERP or MES to ensure full traceability. By connecting frontline feedback with contextual information and performance insights, the platform enables continuous improvement, higher efficiency, and stronger compliance across all operations.

How does flowdit deliver real operational benefits?

By giving frontline employees access to real-time data and standardized digital procedures, flowdit improves productivity, reduces onboarding time, increases safety, and enhances visibility. This integration ensures faster, more accurate decisions while eliminating delays caused by manual operations. Automation empowers workers to solve problems faster and focus on higher-value tasks rather than repetitive activities, fostering an agile inspection and operations management.

How does flowdit improve communication across teams and sites?

flowdit facilitates seamless communication by providing digital tools that enable real-time collaboration between frontline workers, supervisors, and managers. Teams can share updates, insights, and issue reports instantly, reducing delays in information flow. This direct connection helps resolve problems faster and supports continuous improvement. As a result, communication becomes transparent, structured, and tied to real actions on the plant floor.

How does flowdit strengthen workplace safety in daily operations?

flowdit enhances safety by enabling frontline teams to report hazards, incidents, and near-misses in real time while providing instant access to digital work instructions and safety protocols. Integrated alerts and analytics facilitate the identification of persistent threats prior to their escalation into incidents. The platform integrates safety data with audit trails and compliance assessments, guaranteeing full traceability and faster corrective actions. Manufacturing leaders use these insights to strengthen preventive measures and build a safer, more resilient workplace.

How do connected worker platforms enable remote support?

Connected worker platforms link the frontline workforce with experts in real time, enabling them to access technical guidance, documentation, and visual support instantly. Through video calls and augmented reality, complex issues can be resolved without waiting for on-site assistance. This immediate collaboration shortens downtime, improves first-time fix rates, and maintains the flow of production lines. It transforms expertise into a live, on-demand resource in high-stakes manufacturing environments.

How do connected worker platforms manage versioning and retraining?

Procedures are maintained through built-in version control, making sure every update is monitored, reviewed, and approved before release. Once a new version goes live, the system automatically assigns retraining tasks or acknowledgment requests to affected workers. Historical versions remain accessible for audits and traceability. This closed loop ensures that frontline instructions are accurate, compliant, and always improving.

How does flowdit reduce onboarding time?

It offers digital training materials, digital work instructions, and task guidelines to streamline the onboarding process. By giving frontline workers immediate access to interactive instructions, safety protocols, and task-specific checklists, new employees can learn on the job instead of through long classroom sessions. This focus on continuous upskilling, supported by real-time feedback and progress tracking, enables supervisors to spot skill gaps early, driving faster adaptation and consistent performance from the very first day.

How does IoT integration enhance connected worker solutions?

The Internet of Things (IoT) is essential for connected worker platforms, because it enables devices and sensors on the shopfloor to communicate and exchange data. With this connectivity, equipment and processes can be monitored in real time, giving frontline workers actionable insights. The integration of IoT technology enhances decision-making and optimizes manufacturing operations. Ultimately, it contributes to a more efficient and responsive connected workforce.

Which metrics show the real impact of connected worker software?

Productivity rates, worker engagement levels, and safety incident rates are key metrics for assessing the effectiveness of connected worker software. Monitoring these metrics offers a view into how well the connected worker solutions are performing and how they affect manufacturing operations.

How quickly can flowdit be deployed and configured for my operations?

flowdit can be configured and deployed within a few days, perfectly fitting into current workflows and compliance systems. There’s no need for complex IT integration to set it up. Changes are made right away during onboarding. Once configured, teams work productively from day one, with clear transparency and efficiency improvements that can be measured across all locations.