-

Manufacturing Work Instruction Software for Quality and Operations Teams

Digital Work Instructions That Actually Work

Chosen by the Teams That Keep Operations Running

Step-by-Step Instructions

What Are Digital Work Instructions and Why They Matter

Outdated paper instructions cause delays and costly mistakes. Digital work instructions enable you to cut onboarding time by up to 50%, reduce errors and rework, keep instructions instantly updated and accessible on any device, and streamline communication between the shop floor and management.

Why Choose flowdit

flowdit - Built for Manufacturers, Loved by Quality Teams

flowdit is more than software – it’s tailored to meet the real needs of manufacturing and quality teams. User-friendly, flexible, and powerful, flowdit helps you work smarter without complexity. Get started quickly, capture and resolve issues in real time, and generate audit-ready reports effortlessly.

Tailored to Your Needs

Build Workflows with Custom Templates

Instructions On-the-Go

Access Work Instructions Anywhere

Give your teams mobile access to instructions anytime, anywhere -whether in the field or on-site – to complete tasks accurately. Collect real-time feedback directly from your workforce to identify improvement areas and continuously optimize workflows.

Continuous Improvement

Collect Feedback for Process Improvement

flowdit digitizes your work instructions & SOPs with interactive content – videos, images, 3D files, and more – ensuring they are always current and accessible. Operators can quickly create tickets to report issues, capture shop floor data in real time, and perform inline quality controls to keep processes running smoothly.

Transform Your Workflow with

Our Digital Work Instruction Software

Cross-platform compatibility

Secure cloud storage

IoT sensor integration

Real-time collaboration

Offline functionality

Automated workflows

No-code form builder

Data analytics and reporting

GPS tracking

Multi-language support

Mobile-first design

Role-based access control

Perfect fit for every team

Get started fast with out-of-the-box solutions.

Easily customize flowdit as team needs grow!

CONSTRUCTION

flowdit enhances efficiency, reduces delays, boosts productivity, ensures safety.

Project Manager

Granted Works Contractors

LOGISTICS

flowdit unifies operations, boosts efficiency, and enhances team collaboration.

Operations Manager

Loadtrack Logistics

ENERGY

flowdit streamlines processes, boosts efficiency, and empowers innovation.

Sun Horizon Energy Solutions

AVIATION

flowdit transforms operations, ensuring clarity, adaptability, and team alignment.

Chief Operations Officer

SkyTrack Aviation Services

MANUFACTURING

flowdit enhances efficiency, ensures compliance, simplifies processes, and saves time.

Quality Assurance Manager

IronEdge Fabrications

Empower Teams with Integrated Work Instructions

flowdit ensures your data is protected with enterprise-grade security and GDPR, ISO 9001 compliance, giving you peace of mind. Our scalable platform grows with your business, supports multi-language environments, and meets strict industry regulations – making flowdit the trusted choice for teams focused on quality and operational excellence.

How Industries Leverage flowdit as Work Instruction Software

Transform the way your team works - today.

Simplify processes, stay aligned with every standard, and drive efficiency with flowdit’s all-in-one platform. Power your operations today.

Got questions?

Frequently Asked Questions

What is work instruction software?

Work instruction software is a digital tool that helps businesses create, manage, and deliver step-by-step instructions to employees. It is especially important for manufacturing companies, as it simplifies the creation of digital work instructions, visual aids, and electronic work instructions.

By centralizing information, the software ensures tasks are completed accurately and consistently while supporting digital transformation and streamlining processes. Work order integration allows seamless task management, enhancing clarity and coordination. Standard work practices benefit from structured guidance, fostering uniformity across teams.

What are the features of work instruction software?

Digitized Workflows:

Transition seamlessly from manual processes to fully digital workflows, enabling efficient task execution and reducing operational delays.

Standardized Templates:

Use predefined instruction templates to maintain uniformity and clarity across tasks while minimizing errors caused by inconsistent documentation.

Scalability for Growth:

Adapt easily to future needs with scalable solutions that accommodate new processes, revisions, and expanding teams.

Version and Process Control:

Track changes effectively with version control, ensuring only the latest and most accurate instructions are accessible.

Document Permissions and Sharing:

Control who can view or edit documents to maintain data security and streamline collaborative efforts.

Multimedia Integration:

Enhance instructions with images, videos, and interactive elements to improve understanding and engagement.

Reporting and Analytics:

Gain actionable insights into task performance and compliance through real-time reporting and analytics tools.

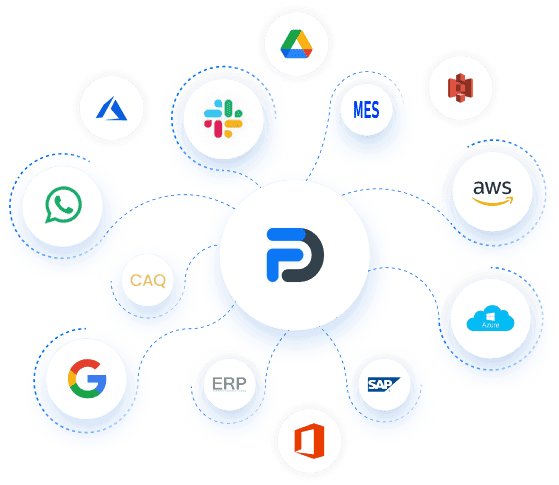

API and Integrations:

Seamlessly integrate with existing systems to connect work instruction software with other enterprise tools for a cohesive digital ecosystem.

Efficient Communication:

Share updates, notify teams of changes, and ensure critical information reaches employees promptly and effectively.

Mobile Accessibility:

Support microlearning and on-the-go training with mobile platforms, enabling employees to access instructions anytime, anywhere.

Centralized Knowledge Access:

A centralized platform for work instructions ensures employees always know where to find information. This minimizes time wasted searching for details and helps teams make quicker, more informed decisions.

Increased Precision:

By detailing every step of a process, work instructions reduce errors and enhance accuracy. This is particularly critical in industries such as manufacturing or healthcare, where precision directly impacts quality and compliance.

Enhanced Productivity:

With clear instructions readily available, employees spend less time troubleshooting and more time executing tasks. This transparency leads to smoother workflows and measurable productivity gains.

Consistency Across Tasks:

Standardized processes ensure tasks are completed the same way every time, minimizing variability and improving reliability in operations.

Improved Collaboration:

By breaking down silos and providing a shared framework for tasks, work instructions foster better communication and teamwork. Employees gain a clearer understanding of their roles and responsibilities within the broader process.

Cost Efficiency:

Streamlined operations and reduced errors lead to cost savings. The right software eliminates inefficiencies caused by outdated systems, freeing up resources for value-added activities.

What are the benefits of using digital work instruction software?

Centralized Document Management:

All instructions are stored digitally in one central repository, eliminating the need for physical storage. Employees can access the documents anytime, whether stored on local servers or the cloud.

Efficient Knowledge Sharing:

Updates or changes can be instantly communicated to all employees without disrupting daily operations. Access to information is available anytime and anywhere, ensuring smooth workflows.

Engaging and Effective Training:

Incorporate visual aids like photos, videos, and interactive quizzes into instructions to make learning intuitive and engaging, accelerating employee understanding and retention.

Streamlined Feedback Mechanisms:

Employees can immediately report process flaws or suggest improvements through the software, enabling managers to address issues promptly.

Process Consistency and Compliance:

Standardized instructions reduce process deviations. Built-in permission requirements ensure that only authorized personnel make updates, maintaining quality and consistency across tasks.

How can work digital work instruction software improve productivity?

Digital work instruction software improves productivity by streamlining workflows and providing step-by-step instructions. It eliminates reliance on outdated paper instructions and integrates standard operating procedures to ensure consistent task execution. Features such as visual work instructions and interactive guides reduce training time and enhance employee accuracy and confidence.

By enabling you to create work instructions efficiently, the software ensures that employees have access to clear and actionable guidance tailored to their tasks. Work instructions can help by reducing errors, improving compliance with processes, and fostering a culture of precision and accountability within your organization.

How can a work instruction software solution reduce errors?

A work instruction software solution helps reduce errors by providing employees with clear, consistent, and centralized instructions for every task. Features like visual aids, real-time updates, and step-by-step digital instructions ensure that processes are followed accurately, minimizing the risk of mistakes.

With step-by-step digital instructions, the valuable expertise of senior employees can be documented and seamlessly shared, ensuring consistent knowledge transfer across the team. Work instructions are easily accessible, eliminating the challenges of searching through filing cabinets for instruction manuals or outdated protocols.

Software for work instruction can also serve as a valuable knowledge base, enabling businesses to simply create instructions for every process and standardize operational procedures. By replacing paper-based methods with guided instruction software, businesses streamline workflows and ensure employees always have access to the right resources at the right time. This centralized and structured approach directly supports error reduction and improves overall efficiency.

Why is work instruction software key to operational excellence?

Centralized Knowledge Access:

Access to work instructions via mobile devices, ensures employees always know where to find information. This minimizes time wasted searching for details and helps teams make quicker, more informed decisions.

Increased Precision:

By detailing every step of a process, work instructions reduce errors and enhance accuracy. This is particularly critical in industries such as manufacturing or healthcare, where precision directly impacts quality and compliance.

Enhanced Productivity:

With clear instructions readily available, employees spend less time troubleshooting and more time executing tasks. This transparency leads to smoother workflows and measurable productivity gains.

Consistency Across Tasks:

Standardized processes ensure tasks are completed the same way every time, minimizing variability and improving reliability in operations. This consistency is vital for maintaining quality standards.

Improved Collaboration:

By breaking down silos and providing a shared framework for tasks, work instructions foster better communication and teamwork. Employees gain a clearer understanding of their roles and responsibilities within the broader process.

Adaptability to Change: An ideal digital work instruction software makes it easy to update instructions in real-time, ensuring teams are always equipped with the latest processes and standards. This adaptability is critical in dynamic industries where requirements evolve frequently.

Cost Efficiency:

Streamlined operations and reduced errors lead to cost savings. The right software application eliminates inefficiencies caused by outdated systems, freeing up resources for value-added activities.

What should I consider when choosing the right software?

When selecting work instruction software focus on solutions that simplify processes and align with your organization’s goals.

Look for tools that support step-by-step instructions and integrate seamlessly with your existing systems. High-quality software must offer features like real-time updates, scalability, and adaptability to industry-specific requirements. A user-friendly editor is crucial, allowing employees to create and modify instructions without the need for extensive training. The software should support multimedia elements such as videos and images, enabling clear and engaging documentation. Intuitive usability ensures faster adoption, while robust version control allows you to maintain a history of changes and revert to previous versions when needed. Tracking changes and notifying users about updates is essential for maintaining collaboration and consistency, especially when multiple contributors are involved. Furthermore, advanced reporting and analytics features provide insights into user engagement, helping you refine processes and measure performance effectively.

Finally, prioritize cloud-based solutions that enable secure storage and easy sharing of instructions. This ensures accessibility for remote teams and facilitates real-time collaboration.

What is the best work instruction software?

The best work instruction software adapts to the specific needs of your organization and enables more efficient work. It offers tailored solutions, flexible templates, and workflows that align precisely with your processes.

Interactive work instructions ensure tasks are clearly defined and easy to follow, helping to minimize mistakes and maintain consistent quality. In the manufacturing industry, the right work instruction software supports precision, scalability, and compliance with industry standards. An ideal tool facilitates collaboration, enhances clarity with interactive content, and ensures scalability. Powerful analytics help optimize workflows, while seamless integration ensures smooth data exchange across departments.

In complex industries like manufacturing, the best software not only reduces errors but also supports continuous learning through intuitive interfaces and mobile accessibility. Focusing on efficiency, compliance, and measurable results maximizes the value of your investment.