Summary: Industrial maintenance ensures the smooth operation of machinery, equipment, and infrastructure in various sectors. It involves preventive and corrective measures to minimize downtime, reduce repair costs, and maintain optimal performance. In recent years, technology has been driving significant changes in the field of industrial maintenance, revolutionizing traditional practices and paving the way for a more efficient and proactive approach. Let’s explore how technology is shaping the future of industrial maintenance and the benefits it brings.

Current Challenges in Industrial Maintenance

Industrial maintenance faces numerous challenges in today’s rapidly evolving landscape. Aging infrastructure and equipment pose significant reliability issues, leading to frequent breakdowns and costly repairs. Furthermore, unplanned downtime can result in significant financial losses for businesses. Another challenge is the lack of proactive maintenance strategies in maintenance management, with many organizations relying on reactive approaches that address issues only after they occur. However, the emergence of advanced technologies is helping overcome these challenges and transforming the industry.

Advanced Technologies in Industrial Maintenance

IoT and Predictive Maintenance

The Internet of Things (IoT) has emerged as a game-changer in industrial maintenance. Connecting devices and equipment to the internet allows valuable data to be collected and analyzed in real-time. This enables predictive maintenance, where maintenance activities are scheduled based on the actual condition of the equipment rather than fixed time intervals. Predictive maintenance plays a crucial role in asset maintenance, ensuring that machinery and infrastructure remain in optimal working condition. By identifying failures before they occur, companies can perform timely repairs, reduce unplanned downtime, and extend the lifespan of critical assets. Additionally, it optimizes maintenance schedules, saving costs and increasing equipment reliability.

How do you optimize industrial maintenance performance?

Maintenance management software turns data into action!

Robotics and Automation

Robotics and automation are revolutionizing industrial maintenance by improving efficiency and safety. Robots can perform repetitive and hazardous tasks, such as inspections and repairs in hazardous environments, with greater precision and accuracy. They can also access confined spaces that may be challenging for human workers. Automated maintenance processes save time and reduce the risk of injuries, as human workers can focus on more complex and strategic tasks. Integrating robotics and automation in industrial maintenance is streamlining operations and enhancing overall productivity.

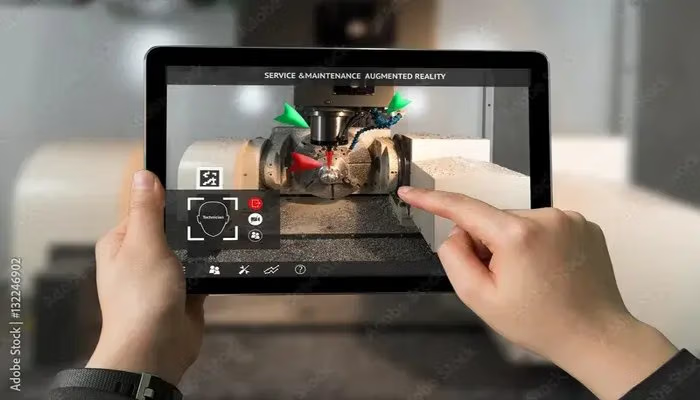

Augmented Reality (AR) and Virtual Reality (VR)

Augmented Reality (AR) and Virtual Reality (VR) technologies are transforming maintenance tasks. AR overlays digital information onto the real-world environment, providing technicians with real-time guidance and instructions during repairs. VR, on the other hand, creates immersive virtual environments that simulate maintenance scenarios for training purposes. These technologies enable remote assistance, where experts can guide on-site technicians through complex procedures, minimizing errors and reducing travel costs. AR and VR enhance the accuracy and efficiency of maintenance tasks while improving overall training and knowledge sharing.

Big Data and Analytics

The abundance of data generated by industrial equipment and processes has given rise to advanced analytics techniques for maintenance optimization. Big Data and analytics enable the collection, storage, and analysis of vast amounts of data to identify patterns, trends, and anomalies. Predictive analytics and condition-based monitoring algorithms can detect early signs of equipment deterioration or failure, allowing for proactive maintenance interventions. By leveraging data, organizations can make informed decisions about maintenance activities, prioritize critical assets, and allocate resources efficiently. This data-driven approach increases equipment reliability, extends lifespan, and reduces maintenance costs.

Artificial Intelligence (AI) in Maintenance

Artificial Intelligence (AI) is revolutionizing industrial maintenance practices. AI-powered algorithms can analyze complex data sets and identify patterns that may indicate faults or performance issues. This enables early fault detection and diagnosis, facilitating timely repairs and preventing costly breakdowns. AI algorithms can also optimize maintenance schedules by considering factors such as equipment usage, historical data, and resource availability. By automating decision-making processes, AI streamlines maintenance operations improves efficiency and maximizes equipment uptime.

3D Printing in Spare Parts Manufacturing

Traditional spare parts manufacturing can be time-consuming and expensive, especially for older equipment models. However, 3D printing technology offers a cost-effective and efficient alternative. With 3D printing, spare parts can be produced on-demand, eliminating the need for large inventories and reducing lead times. This technology also enables the production of complex and customized parts that may be challenging to obtain through traditional manufacturing methods. By embracing 3D printing, organizations can reduce equipment downtime, lower maintenance costs, and improve operational efficiency.

Future Trends in Industrial Maintenance

Blockchain Technology for Supply Chain Management

The Blockchain technology revolutionizes supply chain management in various industries, and industrial maintenance is no exception. Blockchain provides a decentralized and transparent platform for tracking and verifying transactions and data exchanges. In maintenance, blockchain can enhance supply chain management by ensuring the authenticity and traceability of spare parts and equipment components. It helps prevent counterfeiting and fraud, mitigates the risks associated with unreliable suppliers, and streamlines procurement processes. By leveraging blockchain technology, organizations can improve the reliability and efficiency of their maintenance supply chains.

The Role of Cloud Computing

Cloud computing has become a crucial enabler for modern industrial maintenance management systems. Cloud-based platforms offer real-time monitoring and data accessibility from anywhere, allowing maintenance teams to remotely monitor equipment performance and receive instant alerts for potential issues. Collaboration and knowledge sharing among maintenance professionals are also facilitated through cloud-based systems, enabling seamless communication and documentation. Additionally, cloud computing provides scalability and flexibility, as organizations can easily scale their computing resources based on their needs. Adopting cloud computing in maintenance operations enhances efficiency, reduces costs, and enables better decision-making.

Environmental Sustainability in Maintenance

As the world increasingly focuses on environmental sustainability, industrial maintenance has an important role in reducing its ecological footprint. Energy-efficient technologies can be incorporated into maintenance practices to optimize energy consumption and minimize waste. Additionally, recycling and waste reduction initiatives can be implemented to ensure responsible disposal of maintenance-related materials. By adopting green practices, organizations contribute to environmental sustainability while also reaping the benefits of reduced energy costs and improved reputation.

Training and Upskilling the Workforce

With the rapid advancement of technology in industrial maintenance, it is crucial to address the skills gap and ensure that the workforce is adequately trained and upskilled. Continuous learning and development programs can equip maintenance professionals with the necessary knowledge and skills to adapt to new technologies and practices. Training initiatives can focus on areas such as IoT integration, data analytics, robotics, and cybersecurity. By investing in the training and upskilling of the workforce, organizations can maximize the potential of technology-driven maintenance practices and achieve better operational outcomes.

Cybersecurity Concerns in Industrial Maintenance

While technology brings numerous benefits to industrial maintenance, it also introduces cybersecurity risks. Connected devices and networks in the IoT ecosystem can be vulnerable to cyber threats, potentially leading to disruptions, data breaches, or physical harm. Organizations must prioritize cybersecurity measures to protect critical infrastructure and sensitive data. Robust security protocols, regular vulnerability assessments, and employee training on cybersecurity best practices are necessary to mitigate risks and maintain a secure maintenance environment.

Regulatory Compliance and Standards

Industrial maintenance operates within specific industry regulations and guidelines to ensure safety, quality, and environmental compliance. Organizations must adhere to regulatory requirements and standards to avoid legal and financial consequences. Compliance involves regular inspections, audits, and maintenance activities to meet regulatory obligations. By staying up to date with industry-specific regulations and standards, organizations can ensure the safety of their workforce, maintain high-quality standards, and operate in an ethical and responsible manner.

FAQ | Industrial Maintenance

How does predictive maintenance benefit industrial organizations?

Predictive maintenance helps industrial organizations by identifying potential equipment failures before they occur. This allows for timely repairs, reduces unplanned downtime, and increases equipment reliability. It also optimizes maintenance schedules, saving costs and improving operational efficiency.

How can augmented reality and virtual reality be applied in industrial maintenance?

Augmented reality (AR) and virtual reality (VR) technologies assist technicians during maintenance tasks by providing real-time guidance and instructions. AR overlays digital information onto the real-world environment, while VR creates immersive virtual environments for training purposes. These technologies enhance accuracy, reduce errors, and improve overall maintenance efficiency.

What role does big data and analytics play in industrial maintenance?

Big data and analytics enable the collection, storage, and analysis of large amounts of data generated by industrial equipment and processes. By identifying patterns, trends, and anomalies, organizations can make informed decisions about maintenance activities, prioritize critical assets, and allocate resources efficiently. This data-driven approach increases equipment reliability, extends lifespan, and reduces maintenance costs.

How does 3D printing benefit spare parts manufacturing in industrial maintenance?

3D printing technology allows for on-demand production of spare parts, eliminating the need for large inventories and reducing lead times. It also enables the production of complex and customized parts that may be challenging to obtain through traditional manufacturing methods. 3D printing reduces equipment downtime, lowers maintenance costs, and improves overall operational efficiency.

Why is cybersecurity important in industrial maintenance?

As technology becomes more integrated into industrial maintenance, cybersecurity becomes crucial. Connected devices and networks in the IoT ecosystem can be vulnerable to cyber threats, which may lead to disruptions, data breaches, or physical harm. Implementing robust security protocols, conducting regular vulnerability assessments, and training employees on cybersecurity best practices are essential to maintain a secure maintenance environment.

Image: Adobe Stock – Copyright: © zapp2photo – stock.adobe.com