Summary: In today’s competitive business environment, organizations must strive for efficiency, agility, and waste reduction to stay ahead. Lean Thinking, a philosophy rooted in Toyota’s Production System (TPS), provides a structured approach to eliminating inefficiencies, optimizing workflows, and delivering maximum value to customers.

This article explores the core principles of Lean Thinking, how it differs from traditional process management, and how organizations can apply it to drive continuous improvement.

What Is Lean Thinking?

Lean Thinking is a problem-solving approach that focuses on maximizing value while minimizing waste. Unlike rigid process improvement methodologies, Lean Thinking is a mindset that encourages organizations to continuously assess and refine their operations.

At its core, Lean Thinking involves:

✔ Identifying and eliminating waste (Muda) Any activity that does not add value to the customer.

✔ Reducing unevenness (Mura) – Fluctuations in demand or workload that cause inefficiencies.

✔ Eliminating overburden (Muri) – Excessive stress on people, equipment, or processes.

By addressing these inefficiencies, businesses can increase productivity, reduce costs, and improve quality.

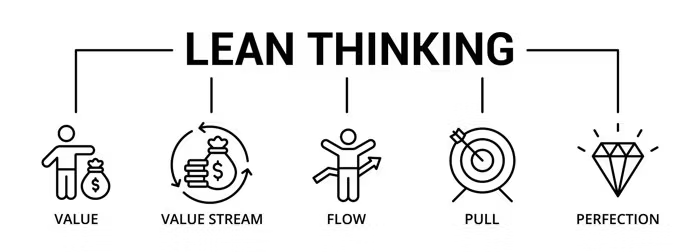

The Five Principles of Lean Thinking

Five core principles guide Lean Thinking, helping organizations create streamlined, waste-free processes.

1. Define Value from the Customer’s Perspective

Companies often focus on internal efficiency rather than customer needs. Lean Thinking starts by identifying what customers truly value and eliminating any activity that does not contribute to that value.

Example: A manufacturer may optimize production speed, but if customers prioritize customization over speed, the company must realign its focus.

2. Map the Value Stream

A value stream represents all steps involved in delivering a product or service. Value Stream Mapping (VSM) helps visualize this process, exposing inefficiencies, redundancies, and waste.

Example: An analysis of a manufacturing line may reveal excessive transportation between departments, increasing lead times.

3. Create Flow

Once waste is identified, the next step is to ensure a smooth, uninterrupted workflow. This involves reducing bottlenecks, improving resource allocation, and eliminating unnecessary steps.

Example: Instead of batch processing, Just-in-Time (JIT) production ensures a steady flow of materials, reducing excess inventory.

4. Establish Pull Systems

Rather than pushing products based on forecasts, Lean Thinking promotes pull systems, where production aligns with real-time demand.

Example: A Kanban system signals production needs only when inventory is low, preventing overproduction and storage costs.

5. Pursue Perfection Through Continuous Improvement

The Lean Mindset is not a one-time project but an ongoing commitment to improvement. By fostering a culture of Kaizen (continuous improvement), organizations remain adaptable and efficient.

Example: A company regularly trains employees to identify inefficiencies, leading to small but consistent process enhancements.

Want to build a more efficient organization? Start with Lean Thinking today.

Discover how Manufacturing Operations Management software supports your efficiency goals.

Lean Thinking and the 7 Wastes of Lean

One of the fundamental applications of Lean Thinking is the elimination of the 7 Wastes of Lean (Muda), which include:

- Overproduction – Producing more than necessary, leading to excess inventory.

- Inventory Waste – Holding unnecessary stock, tying up capital.

- Unnecessary Motion – Inefficient movement of workers, increasing fatigue.

- Waiting Time – Idle time due to bottlenecks or process delays.

- Transportation Waste – Unnecessary movement of materials, increasing costs.

- Overprocessing – Adding features or steps that do not add customer value.

- Defects – Errors requiring rework, increasing costs and reducing quality.

The Lean framework addresses these inefficiencies by implementing structured problem-solving tools, such as Poka-Yoke (error-proofing), 5S organization, and root cause analysis (5 Whys method).

Lean Thinking in Action: Tools for Implementation

1. Value Stream Mapping (VSM)

A visual representation of material and information flow within a process to identify waste and improvement opportunities.

2. Kanban System

A demand-driven pull system that optimizes inventory and production flow by using visual signals.

3. Poka-Yoke (Error-Proofing)

A method that prevents mistakes before they happen through automated checks, visual cues, or fail-safe mechanisms.

4. Just-in-Time (JIT) Production

A system that minimizes inventory costs by producing only what is needed, when it is needed.

5. Kaizen (Continuous Improvement)

A culture of incremental, ongoing improvements led by employees at all levels.

6. 5S Methodology

A workplace organization method focused on Sort, Set in Order, Shine, Standardize, and Sustain to create an efficient work environment.

Benefits of Adopting Lean Thinking

✅ Lower Costs: Eliminating waste reduces operational expenses.

✅ Improved Quality: Minimizing defects enhances customer satisfaction.

✅ Faster Delivery: Streamlined processes shorten lead times.

✅ Higher Employee Engagement: Employees are empowered to improve their work.

✅ Greater Agility: Companies can quickly adapt to changing demands.

By adopting Lean Thinking, businesses not only optimize operations but also build a culture of efficiency and innovation.

Final Thoughts: Why Lean Thinking Matters

Lean Thinking is more than a methodology – it’s a mindset that encourages businesses to continuously improve, eliminate waste, and maximize value.

By applying Lean principles, eliminating Muda, Mura, and Muri, and using proven Lean tools, companies can increase efficiency, reduce costs, and maintain a competitive edge in today’s fast-paced market.

FAQ | Lean Thinking

What is Lean Thinking, and how does it differ from traditional process optimization?

A systematic approach to maximizing value while eliminating waste (Muda), reducing unevenness (Mura), and avoiding overburden (Muri), Lean Thinking goes beyond traditional process optimization.

Rather than making incremental improvements to existing workflows, it challenges the entire value stream, ensuring that each step enhances customer value, efficiency, and adaptability.

How does Lean Thinking drive operational excellence in manufacturing?

It fosters continuous improvement, waste elimination, and standardized processes, ensuring stable production flows, reduced lead times, and improved quality. By aligning production with demand, implementing Just-in-Time (JIT) systems, and using Value Stream Mapping (VSM), manufacturers achieve higher efficiency, lower costs, and increased responsiveness to market changes.

Why is Lean Thinking crucial for quality management?

It directly enhances quality management by reducing defects, process variation, and inefficiencies. Through tools like Poka-Yoke (error-proofing), standardized work, and Kaizen (continuous improvement), organizations can identify root causes of quality issues and implement preventive measures. The focus on flow efficiency and minimal waste ensures that only value-adding activities remain in the process.

How does Lean Thinking integrate with digital transformation in manufacturing?

Lean Thinking and Industry 4.0 complement each other by enabling data-driven decision-making, automation, and predictive analytics. Lean principles ensure that digitalization efforts focus on value creation, rather than adding complexity. Technologies like IoT, AI-driven maintenance, and digital twins align with Lean Thinking by reducing waste, downtime, and process variability while enhancing agility.

What are the biggest hurdles companies face when adopting Lean Thinking?

Many organizations struggle with:

🔹 Cultural resistance: Employees and management may resist change.

🔹 Siloed operations: Cross-functional collaboration is essential but often lacking.

🔹 Misaligned KPIs: Performance metrics should focus on flow efficiency, not just output.

🔹 Sustainability of improvements: Without leadership commitment and structured frameworks, Lean initiatives lose momentum.

🔹 Balancing Lean and flexibility: While Lean focuses on standardization, companies must remain adaptable to market changes.

To overcome these challenges, organizations should invest in training, leadership engagement, and structured Lean frameworks like Hoshin Kanri for strategic alignment.

What strategies ensure long-term success with Lean Thinking?

Sustaining Lean Thinking requires:

✔ A leadership-driven Lean culture that encourages employee involvement.

✔ Regular Kaizen initiatives to foster continuous improvement.

✔ Integrated Lean training across all levels of the organization.

✔ Clear KPIs that measure process flow, efficiency, and waste reduction, not just output.

✔ Leveraging Lean tools like 5S, JIT, Kanban, and TPM to maintain efficiency.

Long-term success comes from embedding Lean Thinking into daily operations, ensuring that process improvement is a continuous, organization-wide effort.

How does Keiretsu relate to Lean Thinking?

Keiretsu networks align with Lean Thinking by fostering long-term supplier relationships, enabling just-in-time production, and ensuring continuous improvement. By integrating suppliers into the value stream, companies minimize waste, enhance quality, and create a more resilient supply chain – key principles of Lean. Toyota’s success with Lean owes much to its strong Keiretsu ties, allowing seamless collaboration and shared innovation.

Image: Adobe Stock – Copyright: © akhmad – stock.adobe.com